Efficient AC Power: SiC and Si Chip Parallel IPM – Revolutionizing Power Conversion

The quest for efficient and reliable power conversion is constantly driving innovation in the power electronics industry. A significant leap forward is being made with the introduction of Silicon Carbide (SiC) and Silicon (Si) chip parallel Intelligent Power Modules (IPMs). This technology promises to revolutionize AC power applications, offering significant improvements in efficiency, size, and cost-effectiveness. This article delves into the specifics of this groundbreaking technology and explores its potential impact across various sectors.

What is a Parallel IPM?

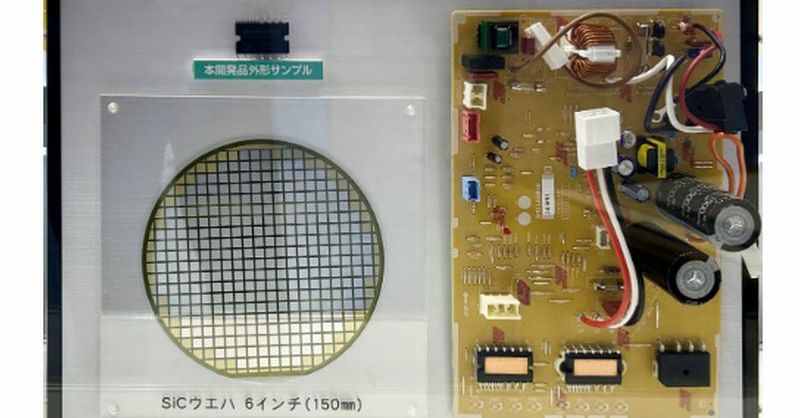

An Intelligent Power Module (IPM) integrates power semiconductor devices, gate drivers, and protection circuits into a single compact package. This simplifies design and improves reliability. A parallel IPM takes this a step further by combining different semiconductor technologies, such as SiC and Si, in parallel operation. This strategic combination leverages the strengths of each technology to optimize overall performance.

The Synergistic Power of SiC and Si

-

Silicon Carbide (SiC): Known for its wide bandgap, SiC MOSFETs offer superior switching speeds, lower conduction losses, and higher operating temperatures compared to traditional silicon-based devices. This translates to increased efficiency and reduced heat generation, particularly crucial in high-power applications.

-

Silicon (Si): While Si MOSFETs don't match SiC's performance in high-voltage, high-frequency applications, they offer a cost advantage and are readily available with mature manufacturing processes. Using Si in parallel allows for optimized cost and power distribution.

The parallel IPM architecture strategically combines SiC and Si devices. The SiC devices handle the bulk of the power, maximizing efficiency, while the Si devices assist in managing current surges and reducing stress on the SiC components. This synergistic approach delivers a superior solution compared to using either technology alone.

Benefits of SiC and Si Chip Parallel IPMs

The advantages of employing this innovative technology are compelling:

-

Higher Efficiency: The combination of SiC and Si significantly reduces power losses, leading to improved overall efficiency in AC power conversion. This translates to energy savings and reduced operational costs.

-

Smaller Footprint: The enhanced efficiency and high power density of SiC allow for a smaller and lighter IPM, leading to reduced system size and weight. This is particularly advantageous in space-constrained applications.

-

Improved Reliability: The integrated protection circuits within the IPM enhance system reliability and reduce the risk of failures due to overcurrent, overvoltage, or short circuits.

-

Cost Optimization: The strategic use of both SiC and Si components balances performance and cost, making this technology suitable for a wider range of applications compared to solely SiC-based solutions.

-

Reduced Heat Dissipation: Lower losses mean less heat generation, simplifying cooling requirements and reducing the need for bulky and expensive heat sinks.

Applications of SiC and Si Chip Parallel IPMs

This revolutionary technology finds applications across various sectors, including:

-

Renewable Energy Systems: Improving the efficiency of solar inverters and wind turbine converters.

-

Electric Vehicles (EVs): Enhancing the performance and range of electric vehicles through more efficient powertrain systems.

-

Industrial Automation: Improving the efficiency and reliability of motor drives and other industrial power control systems.

-

Data Centers: Reducing energy consumption and improving the efficiency of power supplies in data centers.

The Future of AC Power Conversion

SiC and Si chip parallel IPMs represent a significant advancement in AC power conversion technology. Their superior efficiency, compact size, and cost-effectiveness make them a compelling choice for a wide range of applications. As the technology matures and production scales, we can expect to see even wider adoption and further innovation in this exciting field.

Looking for more information on advanced power electronics? Check out our resources on [link to relevant internal page/external resource].