Energy Savings: Mitsubishi's SiC Technology Reduces Power Loss by a Stunning 79%

The global push for sustainable energy solutions is accelerating, and innovative technologies are playing a crucial role. Mitsubishi Electric's groundbreaking advancements in silicon carbide (SiC) power devices are leading the charge, boasting a remarkable 79% reduction in power loss compared to conventional IGBT modules. This leap forward signifies a major shift in energy efficiency across various sectors, promising substantial environmental and economic benefits.

Revolutionizing Power Efficiency with Silicon Carbide

For years, Insulated Gate Bipolar Transistors (IGBTs) have been the industry standard in power conversion. However, IGBTs suffer from significant power losses, leading to wasted energy and increased operational costs. Mitsubishi's adoption of SiC technology offers a superior alternative. SiC power devices exhibit significantly lower on-resistance and switching losses, resulting in dramatically improved energy efficiency. This translates to:

- Reduced energy consumption: Less energy wasted means lower electricity bills and a smaller carbon footprint.

- Increased system efficiency: Higher efficiency allows for smaller, lighter, and more cost-effective power systems.

- Extended equipment lifespan: Lower operating temperatures contribute to longer component lifespans, reducing maintenance and replacement costs.

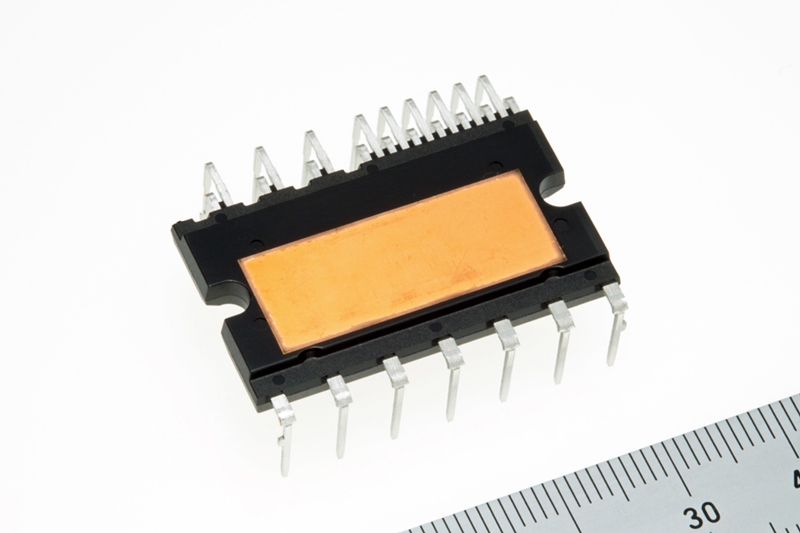

- Enhanced power density: SiC devices allow for higher power density in smaller packages, ideal for space-constrained applications.

Applications Across Multiple Industries

Mitsubishi's SiC technology isn't limited to a single sector. Its impact stretches across various industries, including:

- Renewable energy: Optimizing the performance of solar inverters and wind turbines, maximizing energy harvesting and grid stability.

- Electric vehicles (EVs): Improving the efficiency of EV charging systems and onboard power converters, extending driving range and reducing charging times.

- Industrial automation: Boosting the efficiency of motor drives and other industrial equipment, leading to significant cost savings and reduced emissions.

- Data centers: Minimizing energy consumption in data centers, a critical factor in reducing the environmental impact of digital infrastructure.

The Science Behind the Savings: Understanding SiC's Advantages

The superior performance of SiC stems from its inherent material properties. Compared to silicon, SiC boasts:

- Higher breakdown voltage: Allowing for smaller, more efficient devices.

- Higher electron saturation velocity: Leading to faster switching speeds and reduced switching losses.

- Wider bandgap: Enabling operation at higher temperatures and voltages.

These properties combine to deliver the remarkable 79% reduction in power loss reported by Mitsubishi. This isn't just a marginal improvement; it's a game-changer for energy efficiency.

The Future of Energy Efficiency: SiC's Expanding Role

Mitsubishi's success with SiC technology highlights the growing importance of wide-bandgap semiconductors in achieving global sustainability goals. As research and development continue, we can expect even further advancements in SiC technology, leading to even greater energy savings and a cleaner, more efficient future.

Looking ahead, the widespread adoption of SiC-based power devices promises a significant contribution to a more sustainable and energy-efficient world. Stay tuned for further updates on this revolutionary technology and its transformative impact.

Keywords: Mitsubishi Electric, SiC, Silicon Carbide, Energy Savings, Power Loss, Energy Efficiency, Renewable Energy, Electric Vehicles, IGBT, Wide-bandgap semiconductors, Sustainable Energy, Power Electronics, Green Technology

*(Optional CTA): Learn more about Mitsubishi Electric's innovative SiC solutions by visiting their website [insert link here].