Next-Gen IPM with SiC: Revolutionizing Air Conditioning Efficiency

The quest for energy-efficient cooling solutions is constantly evolving, and a significant leap forward is being driven by the integration of next-generation intelligent power modules (IPM) utilizing Silicon Carbide (SiC) technology. This innovative approach promises to revolutionize air conditioning, delivering significant improvements in energy efficiency and overall performance. Let's delve into how SiC-based IPMs are transforming the HVAC industry.

What are SiC-based IPMs and How Do They Work?

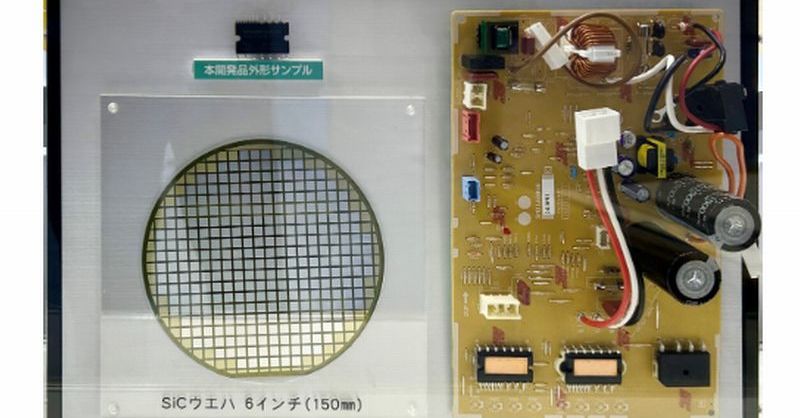

Intelligent Power Modules (IPMs) are pre-assembled, integrated circuits that simplify the design and manufacturing of power electronic systems. Traditionally, these IPMs have relied on IGBT (Insulated Gate Bipolar Transistor) technology. However, SiC MOSFETs (Metal-Oxide-Semiconductor Field-Effect Transistors) offer superior performance characteristics, leading to a new generation of more efficient IPMs.

SiC's inherent properties – higher switching speeds, lower on-resistance, and the ability to operate at higher temperatures and voltages – translate directly into significant benefits for air conditioning systems:

- Reduced Energy Consumption: SiC MOSFETs switch significantly faster than IGBTs, minimizing energy losses during switching transitions. This translates to a substantial reduction in overall energy consumption, leading to lower electricity bills and a smaller carbon footprint.

- Improved Efficiency: Lower on-resistance means less power is wasted as heat, improving the overall efficiency of the air conditioner. This also results in smaller and lighter systems, as less cooling is required for the power electronics themselves.

- Enhanced Reliability: SiC devices are known for their robustness and long lifespan, leading to more reliable and longer-lasting air conditioning units.

- Smaller and Lighter Systems: The improved efficiency allows for the use of smaller and lighter components, leading to more compact and easily installable AC units.

SiC vs. IGBT: A Key Comparison

| Feature | SiC MOSFET | IGBT |

|---|---|---|

| Switching Speed | Significantly Faster | Slower |

| On-Resistance | Significantly Lower | Higher |

| Operating Temp | Higher | Lower |

| Voltage Rating | Higher | Lower |

| Efficiency | Significantly Higher | Lower |

The Impact on Air Conditioning Systems

The adoption of SiC-based IPMs in air conditioners is poised to bring about several significant changes:

- Increased Energy Savings: Significant reductions in energy consumption will lead to considerable cost savings for consumers and reduce the overall energy demand on power grids.

- Smaller Environmental Footprint: Lower energy consumption directly translates to a smaller carbon footprint, contributing to global efforts in combating climate change.

- Improved Comfort: More efficient systems can provide consistent and reliable cooling, enhancing user comfort.

- Technological Advancement: The adoption of SiC technology signifies a substantial step forward in power electronics for HVAC systems, paving the way for further innovations in the future.

The Future of SiC in HVAC

The integration of SiC-based IPMs is still relatively new, but its potential impact is undeniable. As manufacturing scales and costs decrease, we can expect to see wider adoption of this technology across the HVAC industry. This will lead to a more sustainable and efficient cooling sector, benefiting both consumers and the environment.

Looking Ahead: Further Innovations

Research and development continue to push the boundaries of SiC technology. We can anticipate further improvements in efficiency, performance, and cost-effectiveness in the coming years, solidifying SiC's position as a game-changer in the world of air conditioning.

Call to Action: Learn more about the latest advancements in energy-efficient cooling solutions and explore how SiC technology is shaping the future of HVAC. Stay informed about the evolving landscape of sustainable technologies. [Link to a relevant industry resource or whitepaper]