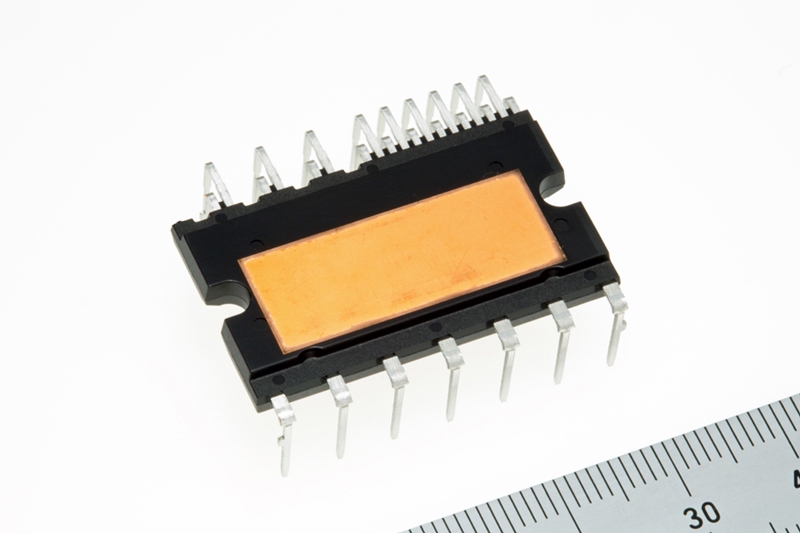

Power Loss Reduced 79%: Mitsubishi's SiC Breakthrough Revolutionizes Power Electronics

Mitsubishi Electric has announced a significant leap forward in power electronics with its new silicon carbide (SiC) modules, achieving a remarkable 79% reduction in power loss. This groundbreaking technology promises to revolutionize various industries, from electric vehicles (EVs) and renewable energy to industrial automation and data centers. The implications are vast, impacting efficiency, sustainability, and the overall performance of countless applications.

A Game-Changer in Power Semiconductor Technology

For years, silicon (Si) has been the dominant material in power semiconductors. However, Si has limitations, particularly at high voltages and frequencies. Silicon carbide (SiC), a wide-bandgap semiconductor, offers superior properties, including higher voltage blocking capability, lower on-resistance, and faster switching speeds. Mitsubishi's achievement represents a major milestone in harnessing SiC's full potential.

Key Advantages of Mitsubishi's SiC Modules:

- 79% Reduction in Power Loss: This is the headline-grabbing achievement, significantly improving energy efficiency across various applications.

- Increased Efficiency: The lower power loss translates directly to higher efficiency, leading to cost savings and reduced environmental impact.

- Higher Power Density: SiC modules allow for smaller and lighter designs, crucial for space-constrained applications like EVs and mobile devices.

- Improved Thermal Management: The reduced power loss also leads to lower operating temperatures, simplifying thermal management and extending component lifespan.

- Faster Switching Speeds: SiC's inherent properties enable faster switching, further enhancing efficiency and performance.

Impact Across Industries: From EVs to Renewable Energy

This breakthrough will have a ripple effect across numerous sectors:

Electric Vehicles (EVs):

- Extended Range: Reduced power loss in EV inverters directly translates to increased driving range on a single charge.

- Faster Charging: Higher efficiency and faster switching contribute to shorter charging times.

- Improved Performance: Enhanced power density leads to more powerful and responsive EV motors.

Renewable Energy:

- Improved Grid Stability: SiC-based power converters can improve the efficiency and stability of renewable energy integration into the power grid.

- Higher Solar Panel Efficiency: SiC inverters can maximize energy harvesting from solar panels.

- Reduced Transmission Losses: More efficient power transmission using SiC technology minimizes energy loss during distribution.

Industrial Automation:

- Increased Productivity: Higher efficiency and faster switching speeds can lead to increased productivity in industrial motor drives and control systems.

- Reduced Energy Costs: Lower power consumption contributes to significant savings in energy costs for industrial operations.

Data Centers:

- Lower Operational Costs: Improved efficiency in power supplies reduces energy consumption and cooling requirements in data centers.

- Increased Server Density: Higher power density allows for more servers in a smaller space.

The Future of Power Electronics: A SiC-Powered Revolution

Mitsubishi's achievement marks a significant turning point in the adoption of SiC technology. As manufacturing scales up and costs decrease, we can expect to see widespread integration of SiC modules across various applications. This technology is not just an incremental improvement; it's a paradigm shift that will reshape the landscape of power electronics, driving sustainability and innovation across industries.

Learn more about silicon carbide technology and its applications by visiting [link to relevant industry resource or academic paper].

Keywords: Silicon Carbide, SiC, Mitsubishi Electric, Power Electronics, Power Loss, Efficiency, Electric Vehicles, EVs, Renewable Energy, Industrial Automation, Data Centers, Wide-bandgap semiconductor, Power Semiconductor, Inverter, High Voltage, High Frequency.