Reduced AC Energy Use: SiC and Si Chip IPMs Revolutionizing Power Efficiency

The global push for energy efficiency is driving innovation across various sectors, and the power electronics industry is no exception. Traditional power management systems are proving increasingly inadequate in meeting the demands of a world striving for sustainability. Enter Silicon Carbide (SiC) and Silicon (Si) chip Intelligent Power Modules (IPMs): a game-changing technology poised to drastically reduce AC energy consumption across diverse applications. This article delves into the specifics of this revolutionary technology and its impact on the future of energy efficiency.

What are SiC and Si Chip IPMs?

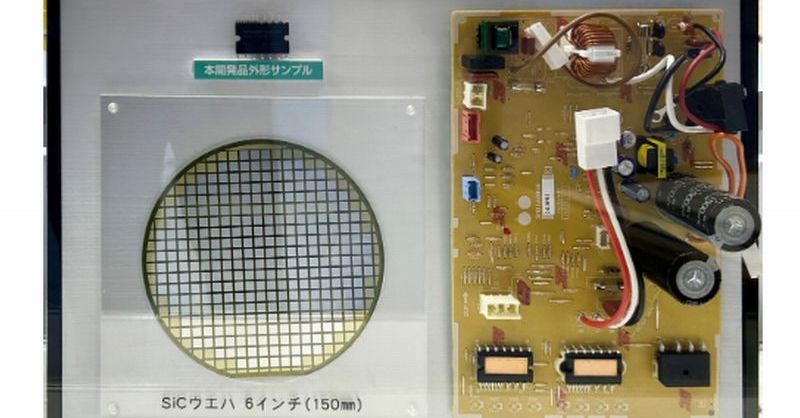

Intelligent Power Modules (IPMs) integrate power semiconductors, gate drivers, and protection circuits into a single compact package. This integrated approach simplifies design, reduces component count, and improves overall system reliability. Traditionally, IPMs have utilized Silicon (Si) technology. However, the emergence of Silicon Carbide (SiC) IPMs represents a significant leap forward in power efficiency.

SiC IPM Advantages:

- Higher Switching Frequencies: SiC devices can operate at much higher frequencies than silicon, leading to smaller passive components (inductors and capacitors) and overall system size reduction.

- Lower Switching Losses: The superior switching characteristics of SiC result in significantly reduced energy losses during switching operations, directly translating to energy savings.

- Higher Power Density: SiC IPMs can handle higher power densities, making them ideal for compact and high-performance applications.

- Improved Efficiency: The combined effect of higher switching frequencies and lower switching losses contributes to substantially improved overall system efficiency. This directly translates to reduced energy consumption and lower operational costs.

- Reduced Heat Generation: Lower losses mean less heat generation, reducing the need for bulky and energy-intensive cooling systems.

Si IPMs: A Cost-Effective Alternative

While SiC IPMs offer superior performance, Silicon IPMs remain a strong contender, particularly in applications where cost is a critical factor. Improvements in Si technology continue to enhance efficiency, making them a viable and cost-effective option for various applications.

- Cost-Effectiveness: Si IPMs are generally less expensive than their SiC counterparts.

- Mature Technology: Silicon technology is well-established, with readily available manufacturing processes and extensive design experience.

- Wide Availability: Si IPMs are widely available from numerous manufacturers, ensuring easy accessibility for designers.

Applications of SiC and Si Chip IPMs

The applications of SiC and Si IPMs are vast and ever-expanding, impacting multiple industries:

- Renewable Energy: SiC IPMs are crucial for optimizing the performance of solar inverters and wind turbine converters, maximizing energy harvesting and grid integration.

- Electric Vehicles (EVs): Higher efficiency and power density are critical in EV applications. SiC and Si IPMs contribute to extended range and faster charging times.

- Industrial Automation: In motor drives and industrial power supplies, these IPMs enable increased precision, efficiency, and reliability.

- Data Centers: With the growing demand for data processing, energy-efficient power supplies using SiC and Si IPMs are crucial for reducing operational costs and environmental impact.

- Home Appliances: Improved efficiency in home appliances, like refrigerators and washing machines, can lead to substantial energy savings on a household level.

The Future of Energy-Efficient Power Electronics

SiC and Si chip IPMs are at the forefront of the revolution in power electronics. Continuous advancements in materials science and semiconductor technology will further improve their performance and reduce their cost, making them increasingly accessible and indispensable for achieving global energy efficiency goals.

Choosing the Right IPM: The optimal choice between SiC and Si IPMs depends on the specific application requirements, balancing performance needs with cost constraints. Careful consideration of factors like power level, switching frequency, and budget is crucial for making an informed decision. Consult with power electronics experts to determine the best fit for your project.

Further Research: For in-depth technical specifications and detailed comparisons of different IPMs, we recommend exploring resources from leading semiconductor manufacturers and industry publications. Stay updated on the latest advancements in this dynamic field to leverage the most efficient power management solutions.