SiC and Si Chip IPMs: Revolutionizing Energy Efficiency

The global push for sustainable energy solutions is driving rapid innovation in power electronics. At the forefront of this revolution are Silicon Carbide (SiC) and Silicon (Si) chip-based Intelligent Power Modules (IPMs). These advanced technologies are significantly improving energy efficiency across various sectors, promising a greener and more sustainable future. This article delves into the specifics of SiC and Si chip IPMs, highlighting their advantages and exploring their impact on diverse industries.

What are SiC and Si Chip IPMs?

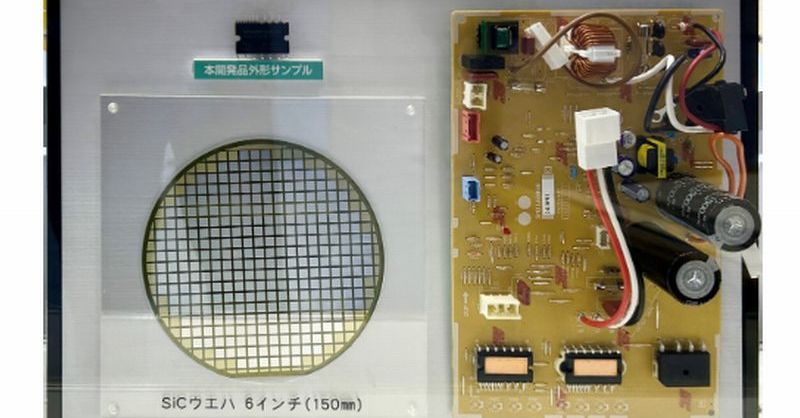

Intelligent Power Modules (IPMs) integrate power semiconductors, gate drivers, and protection circuits into a single compact package. This integrated approach simplifies design, reduces component count, and improves system reliability. The use of SiC and Si chips as the core semiconductor material significantly impacts performance.

SiC IPMs: The High-Performance Leader

Silicon Carbide (SiC) offers superior material properties compared to traditional silicon. This translates to:

- Higher switching frequencies: Leading to smaller, lighter, and more efficient power converters.

- Lower conduction losses: Resulting in reduced energy waste and improved overall efficiency.

- Wider bandgap: Enabling operation at higher temperatures and voltages.

- Increased power density: Allowing for more compact designs in electric vehicles, renewable energy systems, and industrial applications.

These advantages make SiC IPMs ideal for demanding applications where high efficiency and power density are paramount.

Si IPMs: A Cost-Effective Solution

While SiC IPMs offer superior performance, Silicon (Si) IPMs remain a cost-effective and reliable option for many applications. Improvements in Si technology continue to enhance efficiency, making them a viable choice for:

- Lower-power applications: Where the cost benefits outweigh the need for extreme performance.

- Established infrastructure: Where replacing existing systems with SiC may be economically unfeasible.

- High-volume production: Leading to economies of scale and lower per-unit costs.

Applications Across Industries

The improved energy efficiency offered by SiC and Si chip IPMs is transforming multiple sectors:

-

Electric Vehicles (EVs): SiC IPMs are crucial for optimizing the performance and range of electric vehicles, contributing to the widespread adoption of electric mobility. Their high efficiency reduces energy consumption, extending battery life and reducing charging times.

-

Renewable Energy: In solar inverters and wind turbines, SiC and Si IPMs enhance efficiency, maximizing energy harvesting and reducing grid losses. This supports the growth of renewable energy sources and contributes to a cleaner energy mix.

-

Industrial Automation: These IPMs are improving the efficiency of industrial motors and drives, leading to reduced energy consumption and lower operating costs. This is particularly relevant in manufacturing, where energy efficiency is a significant factor.

-

Data Centers: With the increasing demand for data processing, energy efficiency in data centers is crucial. Si and SiC IPMs contribute to reducing energy consumption and operational costs in these facilities.

The Future of Energy Efficiency with SiC and Si IPMs

The ongoing advancements in SiC and Si chip technology promise further improvements in energy efficiency. Research and development efforts are focused on:

- Reducing costs: Making SiC IPMs more accessible for a wider range of applications.

- Improving reliability: Ensuring long-term performance and reducing failure rates.

- Developing new applications: Expanding the use of these technologies into new sectors and markets.

The adoption of SiC and Si chip IPMs is not just a technological advancement; it's a crucial step towards a more sustainable future. By improving energy efficiency across various sectors, these technologies are playing a vital role in reducing carbon emissions and fostering a greener planet. Learn more about the latest advancements in power electronics by exploring resources from industry leaders and research institutions. [Link to relevant industry website/research paper].