SiC IPM: Lower Energy Bills with Parallel Si/SiC Chips – A Revolution in Power Efficiency

Are you tired of sky-high energy bills? Want to reduce your carbon footprint without sacrificing performance? The future of power efficiency might be here, thanks to the innovative application of Silicon Carbide (SiC) Integrated Power Modules (IPMs). This cutting-edge technology, utilizing parallel Si/SiC chips, is poised to revolutionize how we manage power consumption across various industries. Let's delve into the specifics of SiC IPMs and explore how they can help you lower your energy bills significantly.

What are SiC IPMs?

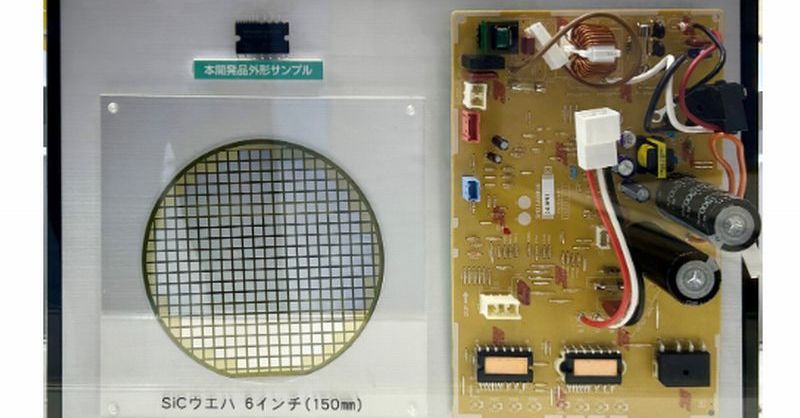

Silicon Carbide (SiC) is a wide-bandgap semiconductor material offering superior performance compared to traditional silicon (Si) in power electronics. SiC IPMs integrate multiple power components – such as transistors, diodes, and gate drivers – onto a single module, minimizing size, weight, and cost. The parallel use of Si and SiC chips in these modules offers a unique blend of advantages:

- Improved Efficiency: SiC's higher switching frequency and lower on-resistance lead to significantly reduced power losses, resulting in greater energy savings. This is particularly beneficial in high-power applications.

- Smaller Footprint: The integrated design of IPMs leads to smaller and more compact power systems, ideal for space-constrained applications.

- Reduced Heat Generation: Lower power losses translate to less heat generated, improving reliability and potentially eliminating the need for bulky and expensive cooling systems.

- Cost-Effectiveness (Long-Term): While the initial investment might be slightly higher, the long-term savings achieved through reduced energy consumption often outweigh the initial cost.

- Enhanced Reliability: SiC's inherent robustness contributes to a longer lifespan and greater reliability compared to traditional Si-based solutions.

How Parallel Si/SiC Chips Enhance Performance

The strategic use of parallel Si and SiC chips within a single IPM optimizes performance by leveraging the strengths of each material. Silicon handles lower power sections efficiently, while SiC takes on the high-power switching tasks, maximizing energy savings and system efficiency. This hybrid approach delivers a cost-effective solution without compromising performance.

Applications of SiC IPMs: Where You'll See the Impact

The applications of SiC IPMs are diverse and rapidly expanding:

- Electric Vehicles (EVs): SiC IPMs are crucial for improving the range and efficiency of electric vehicles, extending battery life and reducing charging times.

- Renewable Energy Systems: In solar inverters and wind turbine converters, SiC IPMs enhance efficiency and reduce energy losses, maximizing energy harvesting.

- Industrial Motor Drives: Improving the efficiency of industrial motors can lead to substantial energy savings and reduced operational costs in factories and manufacturing plants.

- Data Centers: With the increasing demand for computing power, data centers are constantly seeking ways to improve efficiency, and SiC IPMs can play a significant role.

- Power Supplies: SiC IPMs can improve the efficiency of power supplies in various applications, from consumer electronics to medical equipment.

The Future of Power Electronics: Embracing SiC IPMs

The advancements in SiC IPM technology, particularly the use of parallel Si/SiC chips, represent a significant leap forward in power electronics. As the technology matures and production costs decrease, we can expect SiC IPMs to become increasingly prevalent across a wider range of applications, leading to substantial reductions in global energy consumption and a more sustainable future. This innovation promises not just lower energy bills but also a greener and more efficient world.

Ready to Explore More Efficient Power Solutions?

Learn more about the latest advancements in SiC technology by exploring resources like [link to a relevant industry research site] and [link to a reputable manufacturer's website]. The future of energy efficiency is here – are you ready to embrace it?