SiC Technology Breakthrough: Mitsubishi Achieves Stunning 79% Power Loss Reduction

Mitsubishi Electric's groundbreaking advancement in silicon carbide (SiC) technology has sent ripples through the power electronics industry. The company announced a remarkable 79% reduction in power loss using its newly developed SiC power modules. This leap forward signifies a major step towards greater energy efficiency and a significant reduction in carbon emissions. The implications are far-reaching, impacting everything from electric vehicles (EVs) to renewable energy infrastructure.

Revolutionizing Power Electronics with SiC

Silicon carbide (SiC) is a wide-bandgap semiconductor material that offers superior performance compared to traditional silicon (Si) in power electronic applications. Its key advantages include:

- Higher Switching Frequencies: SiC allows for much faster switching speeds, leading to smaller and more efficient power converters.

- Lower On-Resistance: This reduces power losses due to heat generation, a significant factor in improving energy efficiency.

- Higher Breakdown Voltage: SiC can withstand higher voltages, enabling the design of more compact and robust power systems.

- Improved Thermal Conductivity: This characteristic contributes to better heat dissipation, extending the lifespan of components.

These advantages translate directly into significant improvements in energy efficiency, which is why SiC is becoming the material of choice for many high-performance applications.

Mitsubishi's 79% Power Loss Reduction: A Game Changer

Mitsubishi Electric's achievement of a 79% reduction in power loss is a testament to the company's innovative research and development in SiC technology. This significant reduction surpasses previous advancements, demonstrating a substantial leap forward in power electronics efficiency. This breakthrough is largely attributed to:

- Advanced Device Design: Mitsubishi's engineers have refined the design of their SiC power modules, optimizing performance and minimizing energy losses.

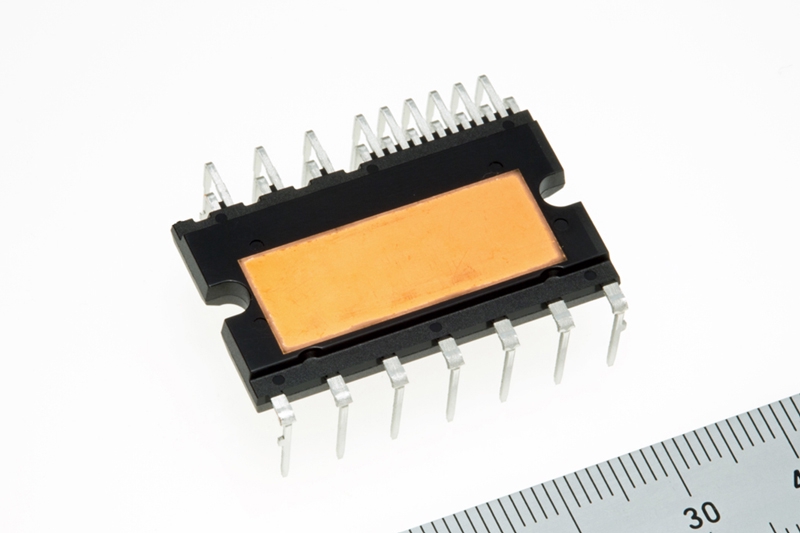

- Improved Packaging Technology: Efficient packaging is crucial for heat dissipation and overall system performance. Mitsubishi's advancements in this area have further enhanced the efficiency of their modules.

- Optimized Manufacturing Processes: Precision manufacturing is vital for consistent high-performance SiC devices. Mitsubishi's improved manufacturing processes contribute to the superior results.

Impact on Various Industries

This breakthrough in SiC technology will have a profound impact on various sectors:

Electric Vehicles (EVs):

The increased efficiency translates to extended driving range and faster charging times for EVs, addressing two major consumer concerns.

Renewable Energy:

SiC power converters are crucial for efficient integration of renewable energy sources like solar and wind power into the grid. Mitsubishi's advancement will contribute to greater stability and efficiency in renewable energy systems.

Industrial Automation:

Improved efficiency in power electronics will lead to cost savings and increased productivity in industrial applications.

Data Centers:

Data centers consume vast amounts of energy. SiC technology can significantly reduce their power consumption, leading to substantial cost savings and environmental benefits.

The Future of SiC Technology

Mitsubishi Electric's success highlights the ongoing evolution and potential of SiC technology. As research and development continue, we can anticipate even greater advancements in efficiency and performance. The wider adoption of SiC is expected to play a critical role in achieving global sustainability goals and driving innovation across multiple industries.

For more information on Mitsubishi Electric's SiC technology and its impact on the industry, please visit [insert relevant link here]. Stay tuned for further updates on this exciting development. What are your thoughts on this groundbreaking advancement in SiC technology? Share your comments below!