Advanced IPM Cuts AC Energy Use: SiC Power Revolutionizes HVAC Efficiency

Introduction:

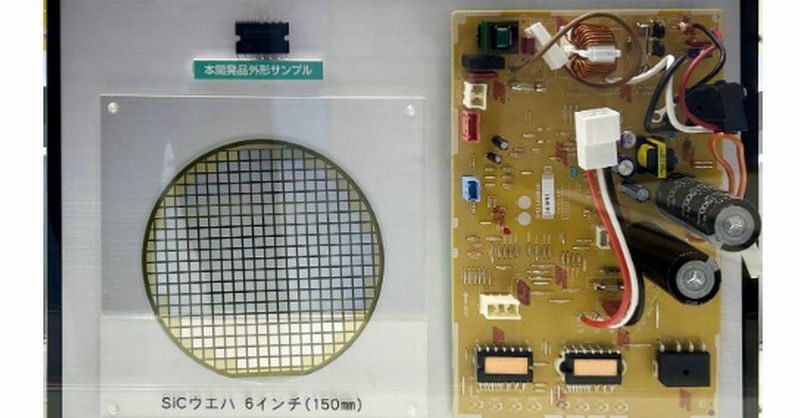

The HVAC industry is under increasing pressure to reduce energy consumption and its environmental impact. A significant leap forward has been achieved with the integration of advanced intelligent power modules (IPM) utilizing Silicon Carbide (SiC) technology. This innovative approach promises substantial energy savings in air conditioning systems, leading to lower operating costs and a smaller carbon footprint. This article delves into the specifics of how SiC power modules are revolutionizing HVAC efficiency, examining their benefits and exploring the future of this exciting technology.

SiC Power Modules: The Heart of Efficient AC Systems

Traditional HVAC systems rely on Insulated Gate Bipolar Transistors (IGBTs) for power conversion. While functional, IGBTs suffer from significant power losses, especially at higher frequencies. This translates directly into wasted energy and increased operating costs. SiC power modules represent a significant upgrade, offering several key advantages:

- Higher Switching Frequencies: SiC MOSFETs can operate at much higher switching frequencies than IGBTs. This allows for smaller, lighter, and more efficient power converters.

- Reduced Switching Losses: The inherent properties of SiC significantly reduce switching losses, leading to a dramatic decrease in energy waste.

- Improved Thermal Management: Lower switching losses mean less heat generation, simplifying thermal management and extending the lifespan of components.

- Smaller System Size: The increased efficiency allows for smaller and more compact AC units, making them ideal for space-constrained applications.

How SiC IPMs Impact Energy Use in AC Systems

The impact of SiC IPMs on AC energy consumption is substantial. Independent studies have shown reductions in energy use of up to 30% compared to traditional IGBT-based systems. This translates to:

- Lower Electricity Bills: Homeowners and businesses alike can expect significant savings on their monthly energy bills.

- Reduced Carbon Footprint: Lower energy consumption directly contributes to a smaller environmental impact.

- Increased System Reliability: The improved thermal management and reduced stress on components contribute to a longer lifespan for the entire AC system.

The Future of SiC in HVAC: A Greener Tomorrow

The adoption of SiC power modules in HVAC systems is rapidly gaining momentum. Major manufacturers are incorporating this technology into their new product lines, driven by consumer demand for energy-efficient solutions and stricter environmental regulations. The future holds even more promise, with ongoing research exploring further advancements in SiC technology to unlock even greater efficiency gains.

Looking Ahead: Key Considerations

While SiC technology offers numerous advantages, it's crucial to acknowledge some challenges:

- Higher Initial Cost: SiC modules currently have a higher upfront cost compared to IGBTs. However, the long-term savings in energy consumption quickly offset this initial investment.

- Supply Chain Considerations: The global demand for SiC is increasing, creating challenges for supply chain management.

Conclusion: Embracing a More Efficient Future

The integration of SiC power modules represents a pivotal moment in the evolution of HVAC technology. By significantly reducing energy consumption and environmental impact, SiC-based AC systems pave the way for a greener and more sustainable future. The long-term benefits of reduced operating costs and increased system reliability make this a compelling choice for both consumers and businesses. As technology continues to advance and costs decrease, the widespread adoption of SiC power modules in HVAC applications is almost certain.

Keywords: SiC Power, Silicon Carbide, IPM, Intelligent Power Module, HVAC, Air Conditioning, Energy Efficiency, Energy Savings, Green Technology, Sustainable HVAC, AC Energy Use, IGBT, MOSFET, Power Conversion, Renewable Energy.

(Optional) Call to Action: Learn more about energy-efficient HVAC solutions by visiting [link to a relevant resource, e.g., a government energy efficiency website or a manufacturer's website].