Efficient AC Power: SiC & Si Chip IPM – Revolutionizing Power Conversion

The demand for energy-efficient power conversion solutions is soaring. Across industries, from electric vehicles (EVs) to renewable energy integration, the need for compact, high-efficiency power systems is paramount. This is where Silicon Carbide (SiC) and Silicon (Si) Chip Integrated Power Modules (IPMs) are stepping in, revolutionizing the landscape of AC power management. This article delves into the advantages of SiC and Si chip IPMs, exploring their applications and the impact they're having on the future of power electronics.

What are SiC and Si Chip IPMs?

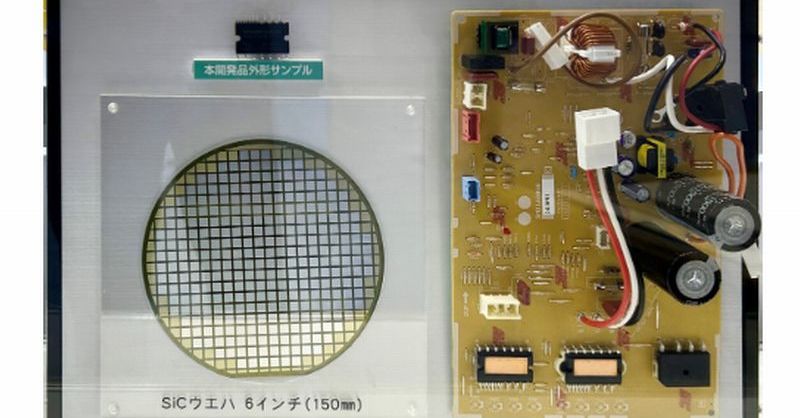

Integrated Power Modules (IPMs) are pre-assembled packages containing all the necessary power semiconductor devices, gate drivers, and passive components for a specific power conversion application. The use of SiC and Si chips significantly enhances their performance and efficiency.

-

SiC IPMs: Silicon Carbide offers superior switching speeds and lower on-resistance compared to traditional silicon. This translates to reduced switching losses, higher efficiency, and the ability to operate at higher switching frequencies. This makes them ideal for high-power applications where efficiency and size are critical.

-

Si IPMs: While not boasting the same extreme performance gains as SiC, Si IPMs still offer significant improvements over discrete components. They provide a cost-effective solution for many applications, offering improved reliability and reduced design complexity.

Key Advantages of SiC & Si Chip IPMs:

- Higher Efficiency: Reduced switching and conduction losses lead to significantly improved overall system efficiency, resulting in lower energy consumption and reduced operating costs.

- Smaller Size and Weight: The integrated nature of IPMs allows for a more compact design, crucial for space-constrained applications like EVs and renewable energy inverters.

- Improved Reliability: Pre-assembled and tested modules minimize the risk of assembly errors and improve overall system reliability.

- Simplified Design Process: IPMs reduce design complexity, shortening development time and reducing engineering costs.

- Lower Total Cost of Ownership (TCO): While initial costs might be slightly higher, the long-term benefits of increased efficiency and reliability contribute to a lower TCO.

Applications of SiC and Si Chip IPMs:

The versatility of SiC and Si IPMs makes them suitable for a wide range of applications:

- Electric Vehicles (EVs): Improving the efficiency of onboard chargers and inverters is vital for maximizing EV range. SiC IPMs are becoming increasingly prevalent in EV powertrains.

- Renewable Energy Systems: Solar inverters and wind turbine converters benefit significantly from the high efficiency and robustness of SiC and Si IPMs.

- Industrial Motor Drives: Improving the efficiency of industrial motors is crucial for reducing energy consumption in factories and other industrial settings.

- Data Centers: Powering the ever-growing demands of data centers requires highly efficient power conversion solutions. Si and SiC IPMs are playing a vital role in this area.

- Uninterruptible Power Supplies (UPS): Reliable and efficient UPS systems are essential for critical applications. Si and SiC IPMs contribute to increased performance and reliability.

The Future of SiC and Si Chip IPMs:

The ongoing advancements in SiC and Si chip technology are continuously improving the performance and cost-effectiveness of IPMs. We can expect to see:

- Wider Adoption: As costs continue to decline, SiC and Si IPMs will be integrated into a broader range of applications.

- Higher Power Density: Further miniaturization and improved thermal management will lead to even higher power density modules.

- Advanced Features: Integration of additional functionalities, such as built-in protection circuits, will further enhance the usability and reliability of IPMs.

Conclusion:

SiC and Si chip IPMs are transforming the landscape of AC power conversion, offering significant advantages in terms of efficiency, size, reliability, and cost-effectiveness. Their widespread adoption across various industries is driving innovation and paving the way for a more sustainable and energy-efficient future. For businesses looking to enhance their power electronics, exploring the potential of SiC and Si chip IPMs is a crucial step towards improved performance and reduced operational costs. Learn more about the latest advancements in power electronics by [linking to a relevant resource, e.g., a whitepaper or industry report].