Enhanced AC Efficiency: SiC & Si Chip IPM Revolutionizing Power Electronics

The quest for greater energy efficiency is driving innovation across multiple sectors, and power electronics are no exception. A significant leap forward is being made with the integration of Silicon Carbide (SiC) and Silicon (Si) chips into Intelligent Power Modules (IPMs). This technology promises to dramatically enhance the efficiency of AC systems, leading to substantial energy savings and reduced environmental impact. This article delves into the specifics of SiC and Si chip IPMs, exploring their advantages and the transformative role they play in modern applications.

What are SiC & Si Chip IPMs?

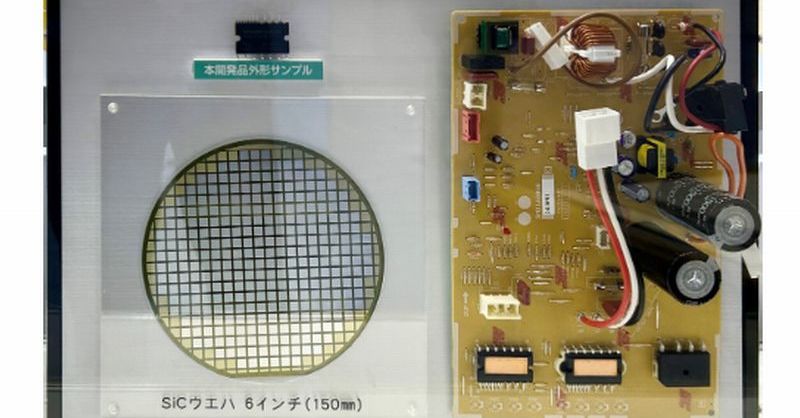

Intelligent Power Modules (IPMs) are pre-assembled power electronic building blocks integrating various components like Insulated Gate Bipolar Transistors (IGBTs), diodes, gate drivers, and protection circuits. Traditionally, IGBTs based on silicon technology have been widely used. However, the emergence of SiC-based IGBTs presents a significant upgrade. SiC chip IPMs leverage the superior properties of Silicon Carbide, resulting in a more efficient and powerful solution compared to their silicon counterparts. Many modern IPMs utilize a hybrid approach, combining SiC and Si chips to optimize performance and cost-effectiveness.

Key Advantages of SiC & Si Chip IPMs:

- Higher Switching Frequencies: SiC devices can switch at significantly higher frequencies than traditional silicon IGBTs. This leads to smaller passive components (inductors and capacitors), resulting in reduced system size and weight.

- Reduced Switching Losses: The faster switching speeds translate directly into lower switching losses, a major contributor to energy inefficiency in power converters.

- Improved Efficiency: The combination of reduced switching losses and lower conduction losses leads to overall higher efficiency, often exceeding 99% in some applications.

- Enhanced Power Density: Smaller components and higher switching frequencies allow for a much higher power density, meaning more power can be packed into a smaller space.

- Lower Operating Temperatures: Reduced losses contribute to lower operating temperatures, improving system reliability and extending lifespan.

- Improved Thermal Management: The reduced heat generation simplifies thermal management, reducing the need for bulky and expensive cooling systems.

Applications of SiC & Si Chip IPMs:

The improved efficiency and performance offered by SiC & Si chip IPMs are driving their adoption across a wide range of applications:

- Electric Vehicles (EVs) and Hybrid Electric Vehicles (HEVs): SiC IPMs play a crucial role in optimizing the performance of EV and HEV powertrains, leading to extended driving range and faster charging times. [Link to article about SiC in EVs]

- Renewable Energy Systems: In solar inverters and wind turbine converters, SiC IPMs enhance efficiency and grid stability. [Link to article about renewable energy applications]

- Industrial Automation: High-performance motor drives and industrial power supplies benefit from the increased efficiency and power density offered by SiC IPMs.

- Data Centers: Efficient power supplies in data centers are essential for reducing operating costs and minimizing environmental impact. SiC IPMs are contributing to this effort.

- High-Voltage DC Transmission (HVDC): SiC IPMs are being increasingly used in HVDC systems for improved efficiency and reduced power losses during long-distance transmission.

The Future of SiC & Si Chip IPMs:

The technology surrounding SiC and Si chip IPMs is constantly evolving. Ongoing research and development focus on further improving efficiency, reducing costs, and expanding applications. We can expect to see even more widespread adoption of this technology as its benefits become increasingly apparent.

Choosing the Right IPM: Considerations for System Designers

Selecting the optimal IPM requires careful consideration of several factors:

- Power rating: Ensure the IPM's power rating meets the application's demands.

- Switching frequency: Higher switching frequencies generally mean higher efficiency but may require more sophisticated control strategies.

- Operating temperature: Choose an IPM capable of withstanding the expected operating temperature range.

- Cost: Balance performance requirements with budget constraints.

The integration of SiC and Si chip IPMs marks a significant advancement in power electronics, paving the way for more energy-efficient and sustainable technologies across various industries. The benefits are undeniable, promising a future where power conversion is more efficient, compact, and environmentally friendly. Are you ready to embrace this technological leap? Contact us today to discuss your power electronics needs.