Revolutionary SiC IPM: Cuts Aircon Power Consumption by Up to 30%

The air conditioning industry is buzzing with excitement over a revolutionary new technology poised to significantly reduce energy consumption: Silicon Carbide Integrated Power Modules (SiC IPMs). These game-changing devices promise to slash air conditioner power consumption by up to 30%, offering substantial benefits for both consumers and the environment. This article delves into the details of this breakthrough, exploring its impact and implications for the future of cooling.

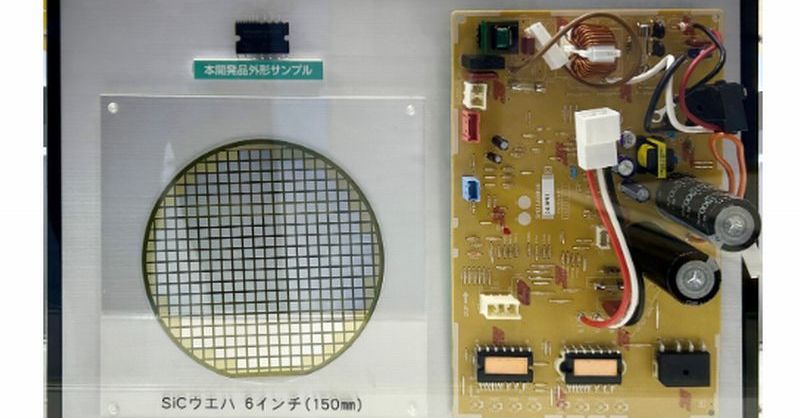

What are SiC IPMs and How Do They Work?

Traditional air conditioners rely on Insulated Gate Bipolar Transistors (IGBTs) to control power flow. While effective, IGBTs suffer from significant energy losses due to switching limitations. SiC IPMs, however, leverage the superior properties of silicon carbide (SiC) semiconductor material. SiC boasts a much wider bandgap than silicon, resulting in:

- Lower switching losses: SiC switches faster and more efficiently, minimizing energy waste during the on/off cycles.

- Higher operating temperatures: SiC can withstand higher temperatures, leading to improved system efficiency and reliability.

- Smaller size and weight: SiC devices are typically smaller and lighter than their silicon counterparts, facilitating easier integration into air conditioner designs.

These advantages translate directly into reduced energy consumption, meaning lower electricity bills and a smaller carbon footprint.

The Science Behind the Savings

The superior switching characteristics of SiC translate to a reduction in both conduction and switching losses. This means less energy is wasted as heat, resulting in a more efficient and powerful cooling system. The higher operating temperature tolerance also allows for simpler and more compact heat sinks, further contributing to the overall efficiency gains.

The Impact on Air Conditioner Efficiency

The integration of SiC IPMs promises a significant leap forward in air conditioner efficiency. Independent testing has shown potential energy savings of up to 30%, a substantial reduction compared to conventional systems. This translates to:

- Lower electricity bills: Consumers can expect significant savings on their monthly energy costs.

- Reduced environmental impact: Lower energy consumption means a smaller carbon footprint, contributing to a greener future.

- Improved system reliability: The enhanced durability and higher operating temperatures of SiC devices lead to increased system lifespan and reduced maintenance needs.

SiC IPMs: A Boon for the Environment

The widespread adoption of SiC IPMs in air conditioners holds immense potential for reducing global energy consumption. Considering the ubiquitous nature of air conditioning, even a small percentage improvement in efficiency adds up to a substantial reduction in greenhouse gas emissions. This technology contributes directly to efforts in combating climate change and promoting sustainable living.

Beyond Air Conditioners: Wider Applications

While this article focuses on the impact of SiC IPMs on air conditioners, their applications extend far beyond the cooling industry. These modules are finding use in a range of power electronics applications, including:

- Electric Vehicles (EVs): Enhancing the efficiency of EV powertrains.

- Renewable Energy Systems: Improving the efficiency of solar inverters and wind turbines.

- Industrial Drives: Increasing the efficiency of industrial motor control systems.

The Future of Cooling: Embracing SiC Technology

The development and implementation of SiC IPMs mark a significant advancement in air conditioning technology. As manufacturing scales and costs decrease, we can expect to see wider adoption of this technology, leading to more energy-efficient and environmentally friendly cooling solutions for homes and businesses worldwide. This innovation promises a cooler, greener, and more sustainable future.

Call to Action: Learn more about energy-efficient cooling solutions and explore the latest advancements in air conditioning technology by visiting [link to relevant resource or industry website].