Innovative IPM: SiC & Si Chips for Efficient Cooling - A Revolution in Thermal Management

The relentless pursuit of higher performance in electronics inevitably leads to increased power density and, consequently, higher operating temperatures. This heat generation poses a significant challenge, limiting device lifespan and efficiency. However, a new wave of innovation in Integrated Power Modules (IPMs) utilizing Silicon Carbide (SiC) and Silicon (Si) chips is revolutionizing thermal management, paving the way for more efficient and reliable electronics. This article delves into the exciting advancements in IPM cooling using these innovative materials.

The Heat is On: Why Efficient Cooling is Crucial

Modern electronics, from electric vehicles (EVs) to data centers, demand increasingly efficient power conversion and control. Higher power densities translate directly to increased heat dissipation requirements. Inefficient cooling leads to:

- Reduced lifespan: Excessive heat degrades components, leading to premature failure and costly replacements.

- Performance throttling: To prevent overheating, devices often throttle performance, reducing overall efficiency and user experience.

- Increased energy consumption: Heat dissipation itself consumes energy, negating some of the efficiency gains from advanced power electronics.

- Safety hazards: Overheating can lead to fires and other safety hazards, especially in densely packed systems.

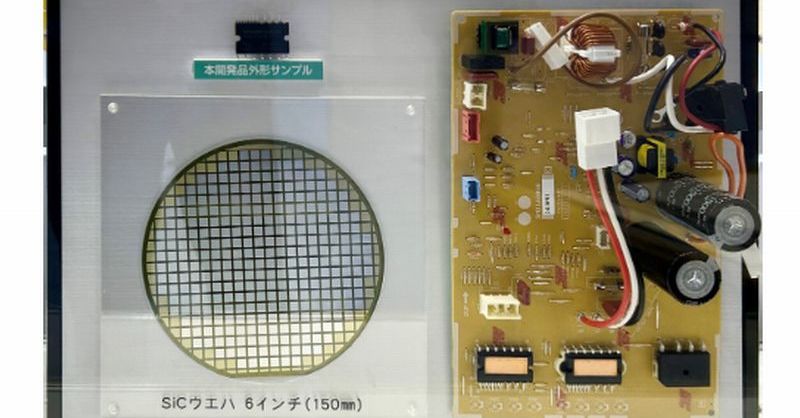

SiC and Si: A Powerful Duo for Thermal Management

Silicon Carbide (SiC) and Silicon (Si) are at the forefront of this thermal management revolution. Their unique properties offer significant advantages:

Silicon Carbide (SiC): The High-Temperature Hero

SiC boasts a much higher breakdown voltage and thermal conductivity compared to traditional silicon. This means:

- Higher switching frequencies: Leading to smaller, more efficient power converters.

- Reduced power losses: Less energy is lost as heat during operation.

- Improved thermal performance: SiC's superior thermal conductivity facilitates better heat dissipation.

Silicon (Si): The Cost-Effective Complement

While SiC offers superior performance, Silicon remains a cost-effective solution, particularly for less demanding applications. Innovations in Si chip design and packaging are improving thermal management capabilities:

- Advanced packaging techniques: Techniques like 3D packaging and embedded die are improving heat transfer.

- Improved materials: Using materials with enhanced thermal conductivity in packaging improves heat dissipation.

- Optimized designs: Careful design of the chip layout and heat sinks can significantly improve thermal performance.

Innovative IPM Designs for Efficient Cooling

The combination of SiC and Si chips within advanced IPM designs is driving significant advancements in cooling technology:

Integrated Heat Sinks:

Many modern IPMs incorporate integrated heat sinks, reducing the reliance on bulky external cooling solutions. These integrated designs improve thermal efficiency and reduce overall system size.

Liquid Cooling Solutions:

For high-power applications, liquid cooling solutions are becoming increasingly common. These systems offer superior heat dissipation capabilities compared to air cooling, enabling higher power densities and improved performance.

The Future of IPM Cooling: Beyond SiC and Si

While SiC and Si are currently leading the charge, research continues into even more advanced materials and cooling techniques. This includes:

- Wide bandgap semiconductors: Materials like Gallium Nitride (GaN) offer even higher performance but are currently more expensive.

- Advanced cooling technologies: Research is ongoing into more efficient and effective cooling methods such as microfluidic cooling and thermoelectric cooling.

Conclusion: A Cooler, More Efficient Future

The integration of SiC and Si chips into innovative IPM designs marks a significant step forward in thermal management. These advancements are crucial for enabling the next generation of high-performance electronics, from EVs and renewable energy systems to data centers and industrial automation. The ongoing research and development in this field promise a future of cooler, more efficient, and more reliable electronics for all.

Keywords: Integrated Power Modules (IPMs), Silicon Carbide (SiC), Silicon (Si), thermal management, efficient cooling, power electronics, heat dissipation, electric vehicles (EVs), data centers, wide bandgap semiconductors, Gallium Nitride (GaN), microfluidic cooling, thermoelectric cooling, 3D packaging, embedded die.